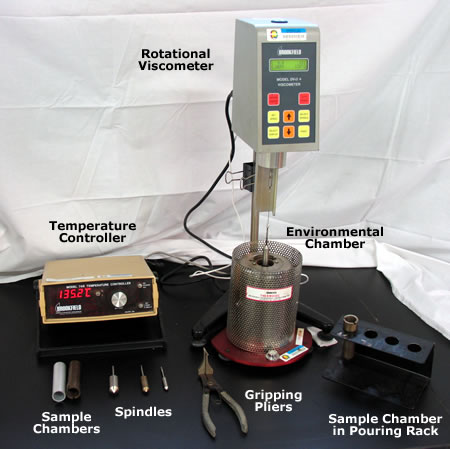

This is what I worked with years back and they have not changed all that much since except having actuators replacing the hand cranks and a PLC attached to the side.

In the original picture that can is a big give away as is the horizontal support being so slim with such a huge control box mounted on it.

What you think is a cutting head is much too big for a tool holder on such a small piece of equipment but is the right size for a strain gauge based torsion sensor

My guess is that drawing a retort stand was more of a challenge than just going with the go-to industrial extrusions for the support fixture and the large control box reflects that the design is a few decades old

I have worked with one like the pic on the right that had a bigger head and sample were in paper coffee cups - super cheap and disposable - which is good since the polymer cures to a very hard and durable insulating material that does not combust easily - which was a very good thing since they were making industrial insulators

and now back to our regularly scheduled sillyness

Sam: Help? My drawstring got pulled into this thing.

Faye: I'm not sure how you even managed to do that.

Bubbles: I think we found our Raven or our Raven found us.

Author

Topic: QC Captions vol. 343 (Read 8175 times)

Author

Topic: QC Captions vol. 343 (Read 8175 times)